Services

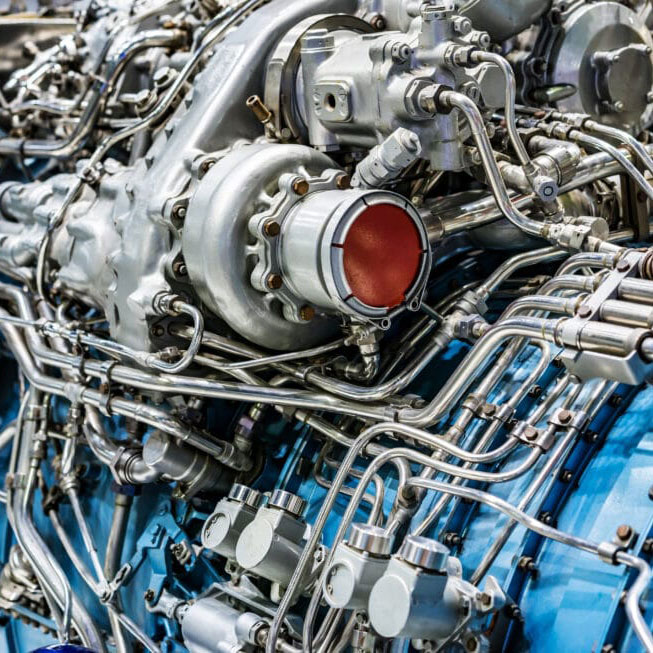

At Profile EDM, we specialize in high-precision Wire EDM machining, Fast Hole drilling, prototyping, and high-volume production. Our advanced technology and expert team ensure tight tolerances, burr-free finishes, and complex geometries with repeatable accuracy.

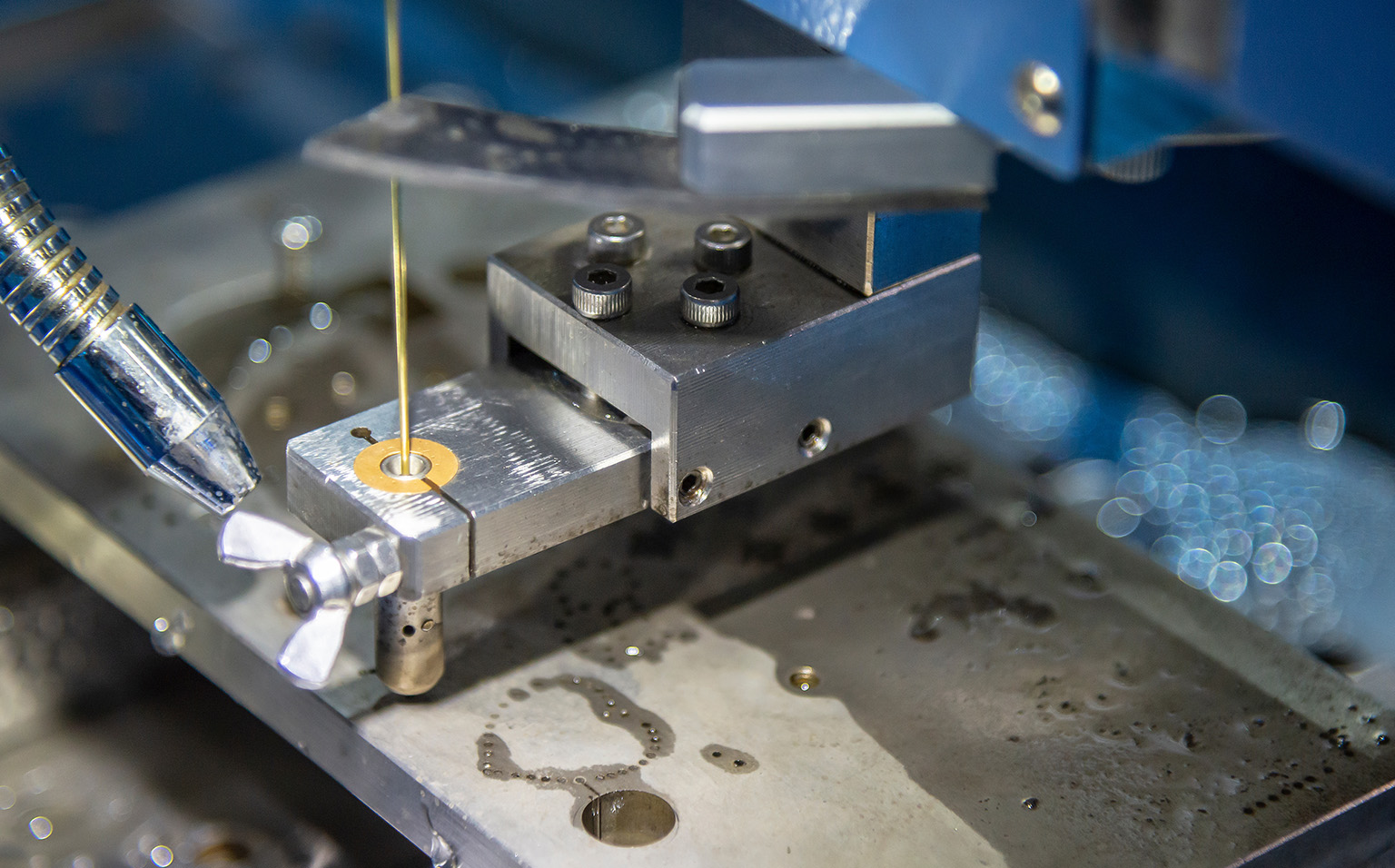

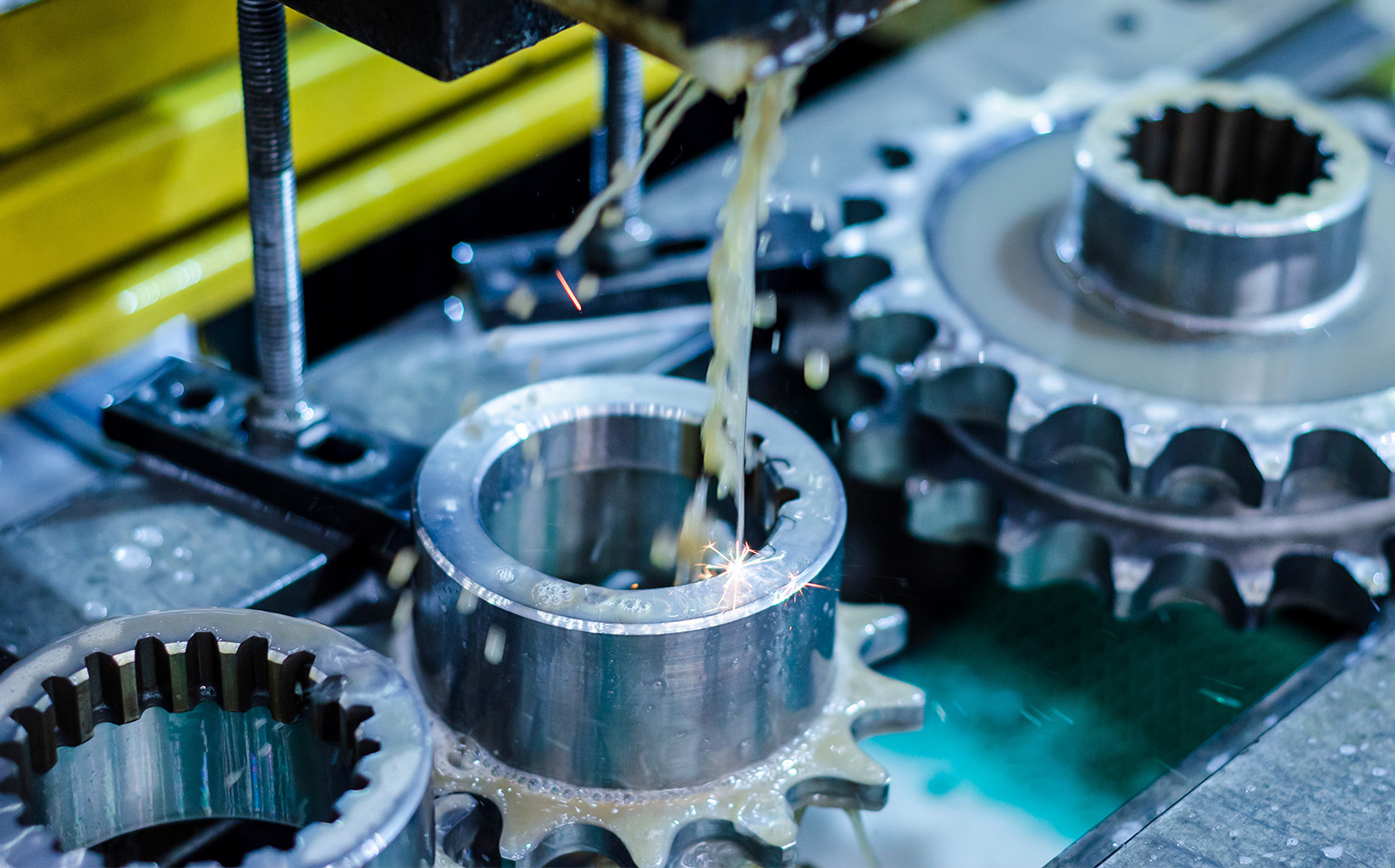

Wire EDM Machining

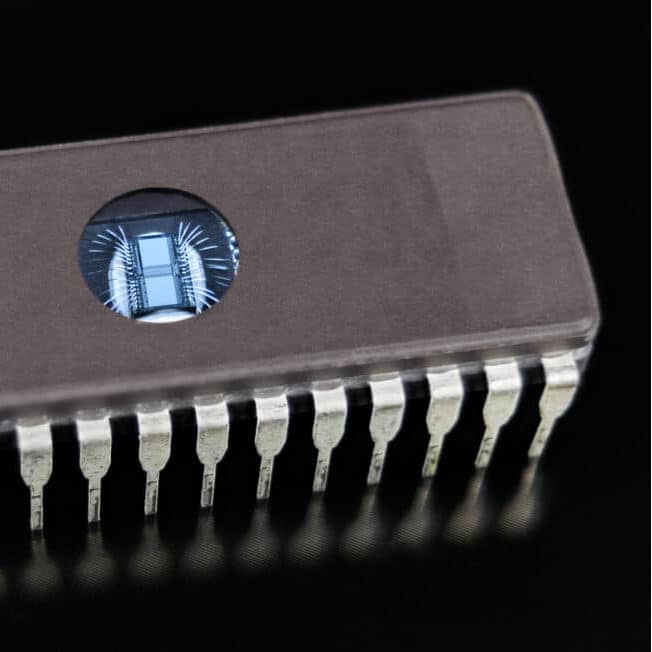

Wire EDM (Electrical Discharge Machining) is ideal for producing intricate parts with tolerances as tight as ±0.0001”. It is a non-contact process that eliminates mechanical stress, making it perfect for delicate and complex designs.

Fast Hole Drilling

Our Fast Hole Drilling technology allows for small-diameter, deep-hole drilling with unmatched precision. This process is commonly used in aerospace, medical, and tooling industries where traditional drilling cannot achieve the required accuracy.

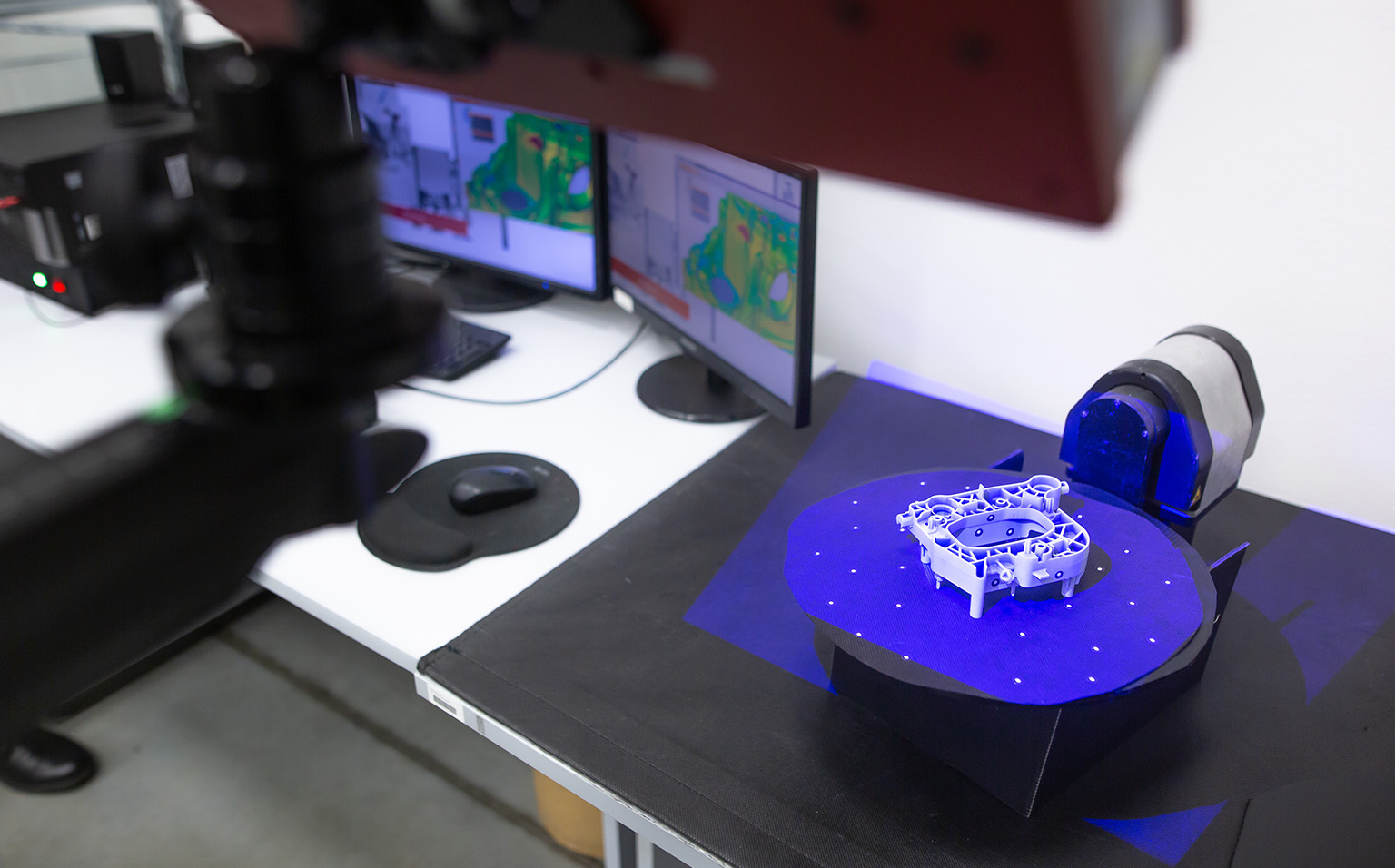

See More DetailsPrototyping & Reverse Engineering

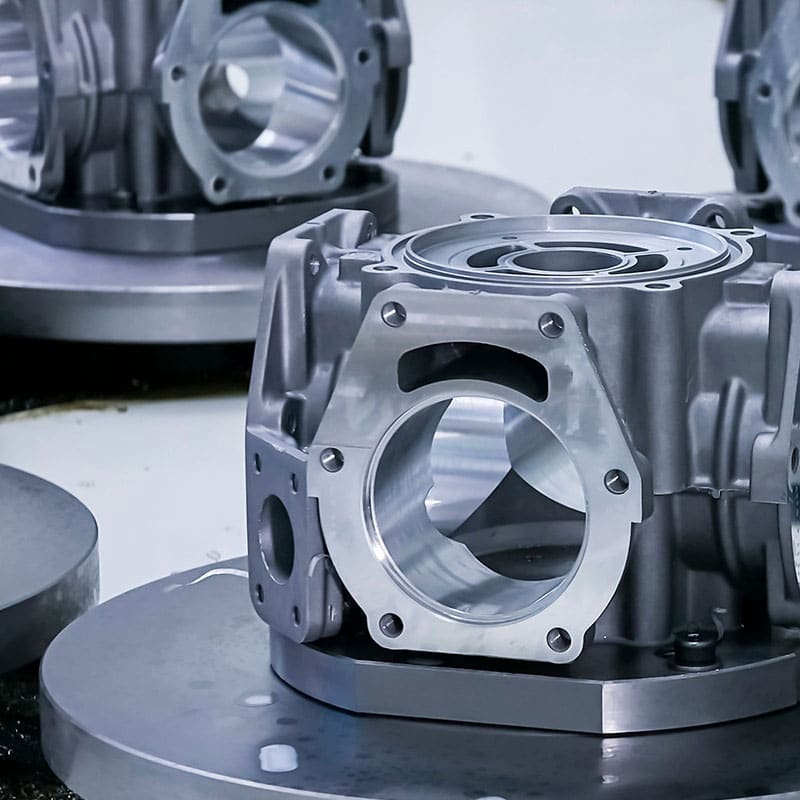

Need a prototype for testing or custom part reproduction? Our CAD/CAM-based reverse engineering solutions provide accurate digital reconstructions of existing components, ensuring exact specifications.

See More Details

High-Volume Production

Our scalable Wire EDM production solutions provide consistent high-accuracy results for OEMs, tool & die shops, and contract manufacturers. We deliver precision parts at scale, ensuring fast turnaround and cost-effective manufacturing.

See More Details