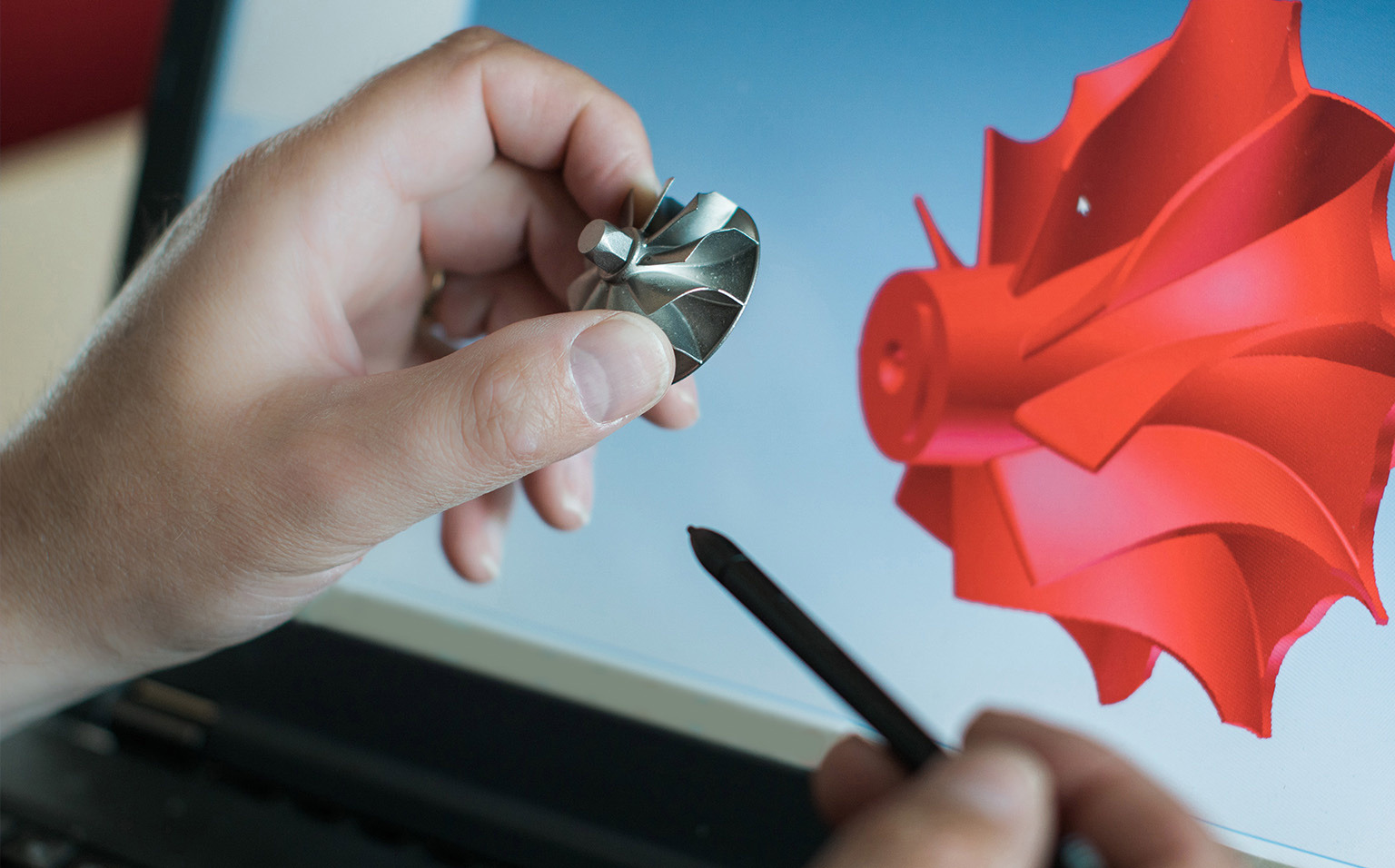

Prototyping & Reverse Engineering

Prototyping and Reverse Engineering services at Profile EDM provide advanced solutions for developing new components, reproducing discontinued parts, and optimizing designs for performance and cost efficiency. Our expertise in CAD modeling, 3D scanning, and precision machining ensures we can accurately replicate and improve existing parts with superior precision.

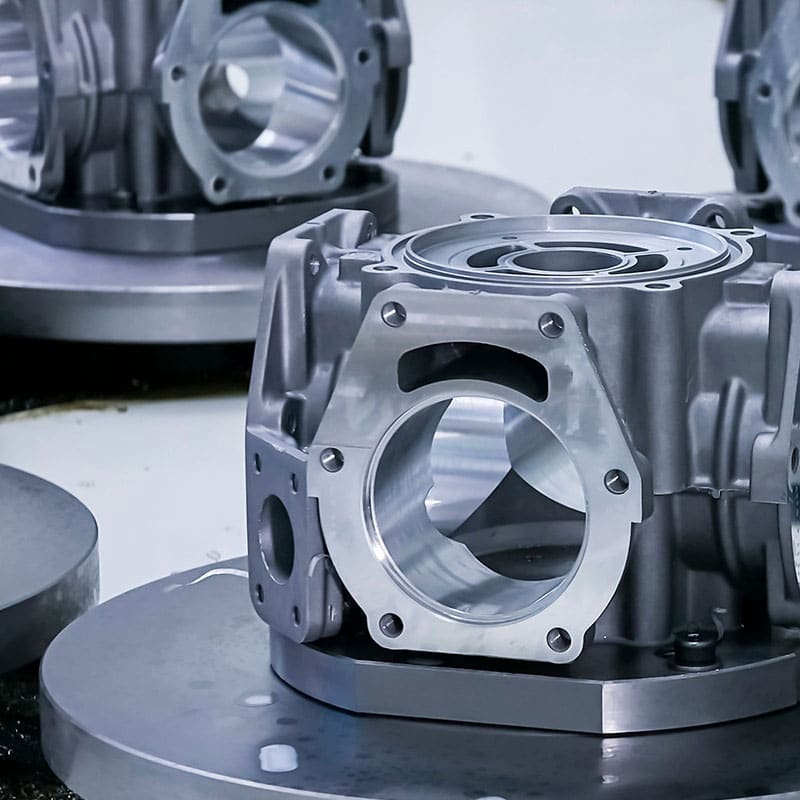

Reverse engineering is essential when OEM replacement parts are unavailable or difficult to find. Instead of altering production processes or investing in costly new equipment, businesses can use our reverse engineering services to reproduce exact or improved versions of worn or broken components. Using high-accuracy scanning and CNC machining, we can create fully functional replacements that seamlessly integrate into existing systems.

At Profile EDM, we apply 3D scanning technologies, CAD software, and coordinate measuring machines (CMM) to analyze and recreate components with extreme accuracy. Our advanced prototyping solutions allow us to develop multiple design iterations quickly, ensuring efficiency, durability, and cost-effectiveness before full-scale production begins.

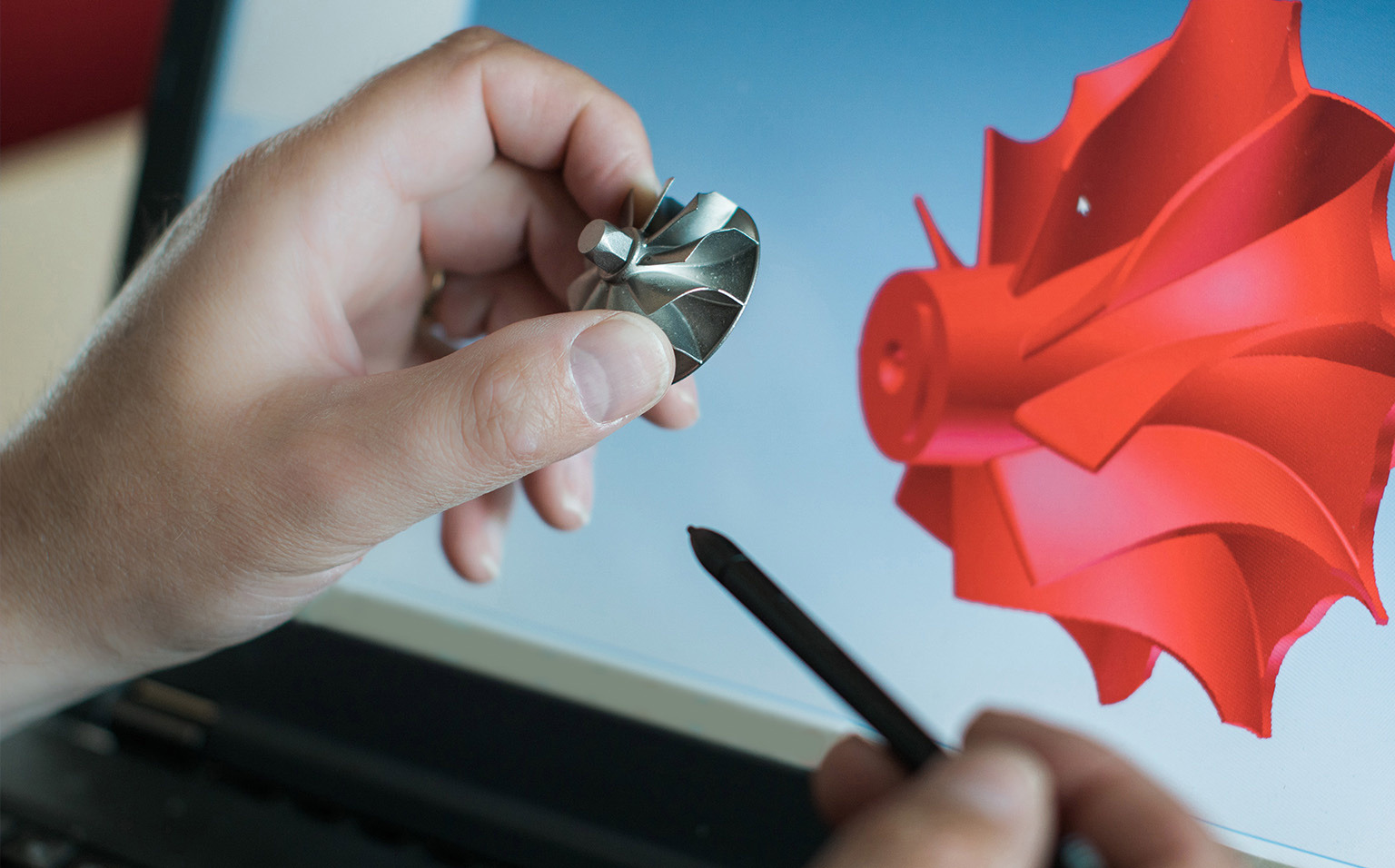

Our reverse engineering process allows us to recreate, refine, or enhance parts to meet modern industry standards. By leveraging 3D modeling and SolidWorks software, we can analyze and improve components before manufacturing begins, ensuring optimal strength, efficiency, and cost-effectiveness.

With advanced coordinate measuring machines (CMM), we extract precise dimensional data from existing parts, allowing us to digitally reconstruct them with incredible accuracy. Our expertise in reverse engineering extends beyond simple duplication; we identify opportunities for optimization, such as material enhancements or design modifications that improve performance and longevity.

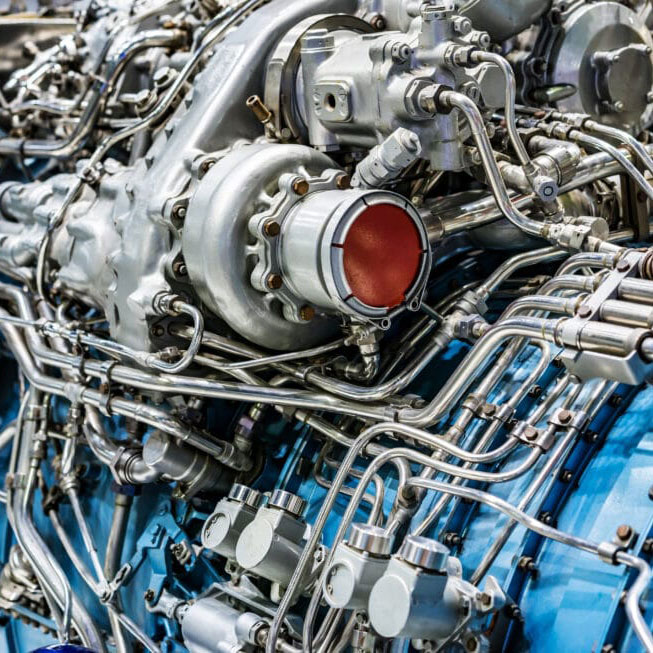

From high-performance aerospace components to critical machine parts, we provide solutions that restore functionality without compromising quality. Our prototyping and reverse engineering services give businesses a cost-effective way to maintain and enhance operations without relying on outdated or unavailable components.

Reverse engineering is a multi-step process that involves precise measurement, modeling, and fabrication. We utilize 3D scanning, laser scanning, CT scanning, and structured light digitizing to capture every detail of a part, ensuring that our final design is an exact match to the original or an optimized improvement.

Data Collection

Gathering detailed measurements of the original part using CMM, 3D scanning, or laser scanning.

CAD Reconstruction

Converting scanned data into 3D CAD models for analysis and refinement.

Analysis & Optimization

Evaluating material strength, design improvements, and cost efficiency.

Prototype Development

Creating prototypes for functional testing and validation.

Final Production

Manufacturing the optimized part using precision EDM and CNC machining.

Quality Inspection

Ensuring all components meet strict tolerances before delivery.

At Profile EDM, we specialize in providing cost-effective, high-precision reverse engineering solutions that help businesses maintain and improve operations. Whether you need legacy part reproduction, precision prototyping, or design optimization, we deliver unmatched accuracy and quality in every project.