About Us

Profile EDM offers both wire EDM machining and EDM hole drilling services, utilizing state-of-the-art, CNC-operated production equipment to give our customers precision parts and components that match their unique design specifications.

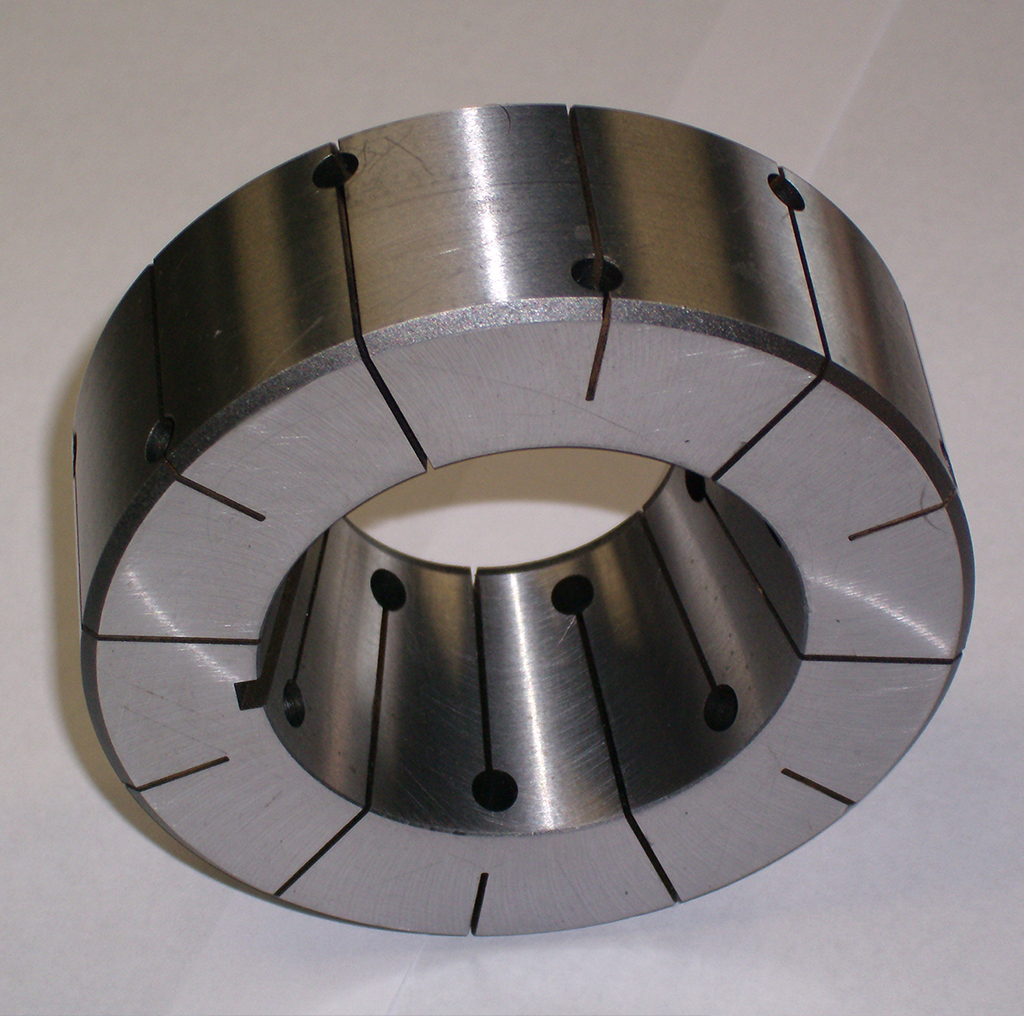

Wire EDM Machining Services

With state-of-the-art wire EDM machining equipment and advanced programming, we can manufacture even the most intricate parts with perfect accuracy and repeatability, whether you need prototypes, short production runs, or quantities in the thousands.

Rapid Drilling Capabilities with High Precision & Accuracy

EDM hole drilling offers extremely high dimensional accuracy and results in drilled holes with fine finishes that require no additional work to remove burrs or smooth the surface.

Why Profile EDM

Engineering

Our engineers have the capability to reverse engineer parts providing a robust approach to manufacturing.

Service

We provide service to a multitude of industries and guarantee your part will be cut right the first time.

Scheduling

We offer pick up and drop off services and run multiple shifts to accomodate rush and emergency needs.

Frequently Asked Questions

What is EDM?

Electrical Discharge Machining, also known as wire-cut EDM and wire cutting, is an electro thermal production process where a thin single stand of metal wire (usually brass) along with de-ionized water (used to conduct electricity) allows the wire to cut through the metal by the use of heat from electrical sparks.

Why use EDM wire cutting?

Production of pieces accurate to +/- .0001” with virtually no burrs since not cutting forces are present. Internal corner cuts with nearly square edges. Delivery times are short since not tooling is required. Tools and parts can be machined after heat treatment so dimensional accuracy is held. Ability to produce delicate and intricate parts accurately and repeatedly with no deflection.

Who are our clients?

We work with companies that have in-house EDM departments to help supplement their existing capabilities as well as companies such as tool and die shops that do not have in-house wire EDM capabilities. We also work with many other OEM and contract manufacturers in a variety of industries.

What are some of our other services?

We offer prototyping, reverse engineering, laser marking, small hole wire EDM, high volume production and other services including the ability to remove broken drills and taps.

What types of files can we read?

We boast a full CAD/CAM department with the ability to open and/or translate nearly any format of CAD file? Please inquire directly as these abilities are enhanced frequently.

How many years have we been in the industry?

Our team is comprised of industry specialists with over 30 years of EDM experience and familiar with industry requirements, standards, and practices. Let our experts go over your requirements and ask the right questions based on years of production experience.

Contact Us

Our Address

50571 E Russell Schmidt Blvd, New Baltimore, MI 48051

Email Us

Call Us

586-949-4586